UV curing enables reliable, faster and more consistent production of substrates with varnish coatings. The video illustrates how wide-web converters can benefit from GEW’s fully air-cooled NUVA2 UV systems.

The NUVA2 lamphead is available in widths of up to 2.50m and boasts particularly fast switch-on and cool-down cycles achieving considerable electricity and time savings. It addresses the specific requirements of converters who need to coat substrates in extreme widths.

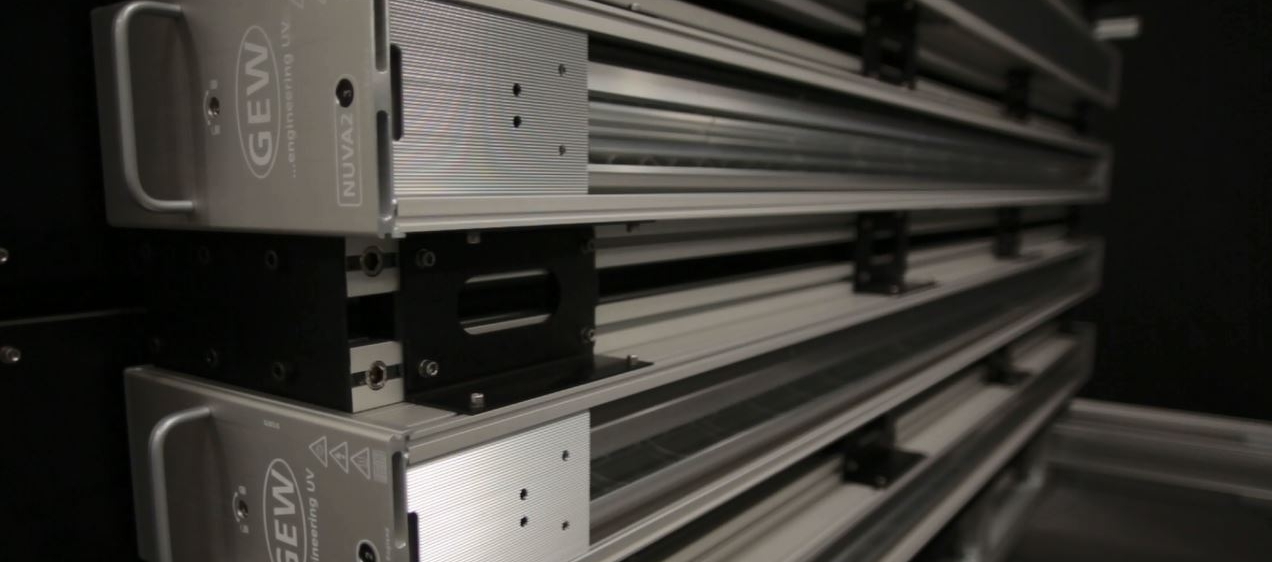

Likora GmbH in Germany upgraded the final varnish curing station on one of their gravure printing lines with the new UV-curing system replacing an older system. To this purpose they integrated three GEW-made 240cm-wide NUVA2 UV lampheads with RHINO power supply. The three UV lampheads are positioned vertically one after the other so as to achieve the maximum UV-curing effect. The UV system is mounted in a custom designed aluminium frame that integrates a retractable cooling panel and water-cooled quartz window to prevent the heat transfer onto the substrate.

The configuration is now able to print and varnish substrates up to 2350mm wide with speeds up to 120m/min and mainly produces finish foils intended for wrapping and laminating on wood-based materials.

Watch the video below to find out more about NUVA2:

This is just one example of how GEW can help, by creating bespoke UV curing solutions tailored to your individual requirements. Contact our sales team to discuss how we can help you:

Speak directly to our Sales team

Region, Americas:

Jennifer Heathcote

Vice President, Business Development

Email Jennifer directly