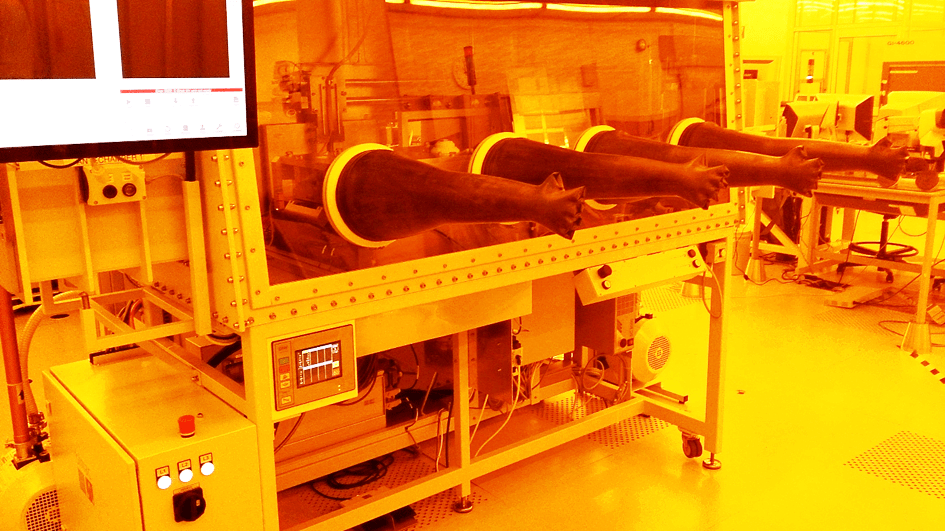

In this specialised clean room application, the manufacturing process of OLED displays requires exposing the products while being manipulated in a glove box.

The surface to be exposed is 35cm square. The floorplate inside the glove box has partially been replaced by a solid quartz window.

The UV lamphead, a 30cm-wide GEW E2C, is mounted underneath at a specific distance. A reflective shaft between the lamphead and the glove box ensures an even distribution of the UV radiation over the surface. An integrated UV sensor measures the level of UV exposure to ensure every part is consistently exposed with the required UV energy dose.

This is just one example of how GEW can help, by creating bespoke UV curing solutions tailored to your individual requirements. Contact our sales team to discuss how we can help you:

Speak directly to our Sales team

Region, Americas:

Jennifer Heathcote

Vice President, Business Development

Email Jennifer directly