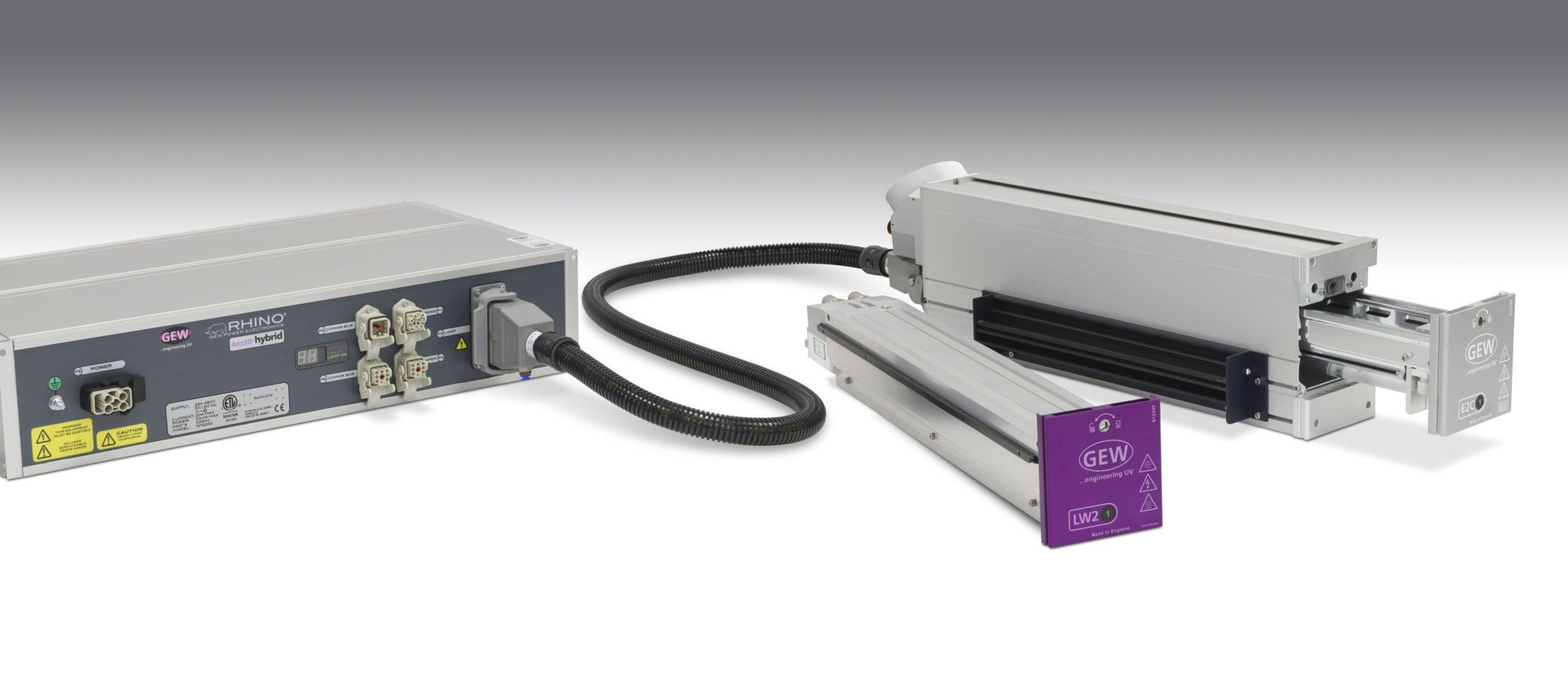

GEW has launched ArcLED, a futureproof hybrid UV curing system that allows an investment in arc technology now that can be upgraded later with LEDs using the same lamphead casing, and the same power supply and control.

GEW said the transition towards UV curing of inks and varnishes with LEDs has begun, although in many situations the move is technically and financially not fully understood to make an investment in a machine fully equipped with LEDs.

The launch of ArcLED is intended to address this situation and meet the needs of printers by allowing arc curing technology to be upgraded at a later stage to LEDs.

With ArcLED, the LED cassette required is fitted, as is a water cooling system (already available on many machines), and the GEW Rhino ArcLED power supply then automatically recognizes which type of cassette is installed in the machine and adjusts the Rhino control accordingly.

This unique combination of quick-swap lampheads, reactive detection of the required power and automatic switching will optimize processes, maximize ink compatibility and increase machine productivity, according to GEW.

GEW said ArcLED is an industry first, and allows seamless switching on the same press with the same Rhino power supply from DC power for the LEDs to high voltage AC for the arc lamps.

The Rhino ArcLED power supply is also said to be extremely energy efficient and shows considerable energy savings when compared to conventional electronic power supplies.

GEW Rhino ArcLED curing systems are supplied, as standard, with GEW’s Embedded Service package which allows remote monitoring of the system running condition, so allowing the manufacturer’s service engineers to detect and correct out of tolerance parameters.

Further, GEW offers all Rhino systems with a comprehensive five-year warranty.

‘An investment now in GEW’s ArcLED UV curing protects that investment into the future by ensuring an LED upgrade can be simply and cost-effectively implemented,’ GEW said. ‘It also gives the possibility to run a fully flexible hybrid curing system.’

An ArcLED case study

A good example of ArcLED in practice is the case of Eurolabel.

Eurolabel is an established company in the self-adhesive label market, based near Milan in Italy. With a premises of over 5,000m2 and 20 production lines, Eurolabel are a leader in their market segment.

Eurolabel use a mixture of GEW’s air-cooled mercury arc UV lamp, E2C, and the water-cooled mercury arc UV lamp, E4C, alongside GEW’s water-cooled LED system, LeoLED. These curing systems are installed on their Gallus LabelMasters.

For Eurolabel, the ArcLED technology was particularly appealing, with CEO Aldo Franco saying: “We are satisfied with the use of LED, especially in terms of quality. Perfect curing of the ink is a very important factor for us: avoiding the risk of ink transfer on the roller and, in general, improving the efficiency of the production cycle and machine setup are key. We are currently using both technologies combined but our intention is to switch to LED technology alone, as soon as possible.”

Read the full Eurolabel case study here. You can also watch the case study video on the same page.